Energy consumption and cost of utilities can be measured on the basis of hour, day, month, or year, by individual, aggregated departments, or corporate level. By setting benchmarks and comparing current performance with set targets, it is easy to analyze the use of energy and utilities to support energy efficiency improvements.

Real-time Data Management

Performance calculation, data displays and reports can be easily visualized using dashboard tools. The navigation menu and dashboard displays can be customized from the user interface, including trends, graphs, diagrams and tables. It also provides KPI and alarm management functions.

Dashboard Visualization

Why Choose Us

Energy management combined with production management is crucial for centralized operation optimization and control

-

Easy deployment and maintenance

Single platform for automation and energy management allows fast implementation, easy scalability, user-friendly maintenance, and seamless integration with 3rd party software and database.

-

Data integration

The digitally enabled convergence of information technology and operation technology provides the infrastructures to navigate the energy management landscape for operation excellence.

Reducing project lead time and providing value-added services is important for future-ready business

-

Customizable and expandable service

Simple, intuitive interface with easy configuration tools and tailor-made dashboards enable high reliability and flexibility to develop value-added services with reduced project time, risk and costs.

-

New business opportunities

With rapid project implementation and value-added services, competitive advantage and new business opportunities can be earned today to comply with tomorrow.

Energy Management Systems (EMS) are automation systems that collect energy measurement data from the field and making it available to users through graphics, online monitoring tools, and energy quality analyzers, thus enabling the management of energy resources.

Energy Management Systems can reduce operating costs and improve productivity. Meanwhile, energy management systems should meet the automation requirements of energy equipment and operation management, so that energy management systems can reduce the input of human resources.

Digitizing Energy Management with EMS

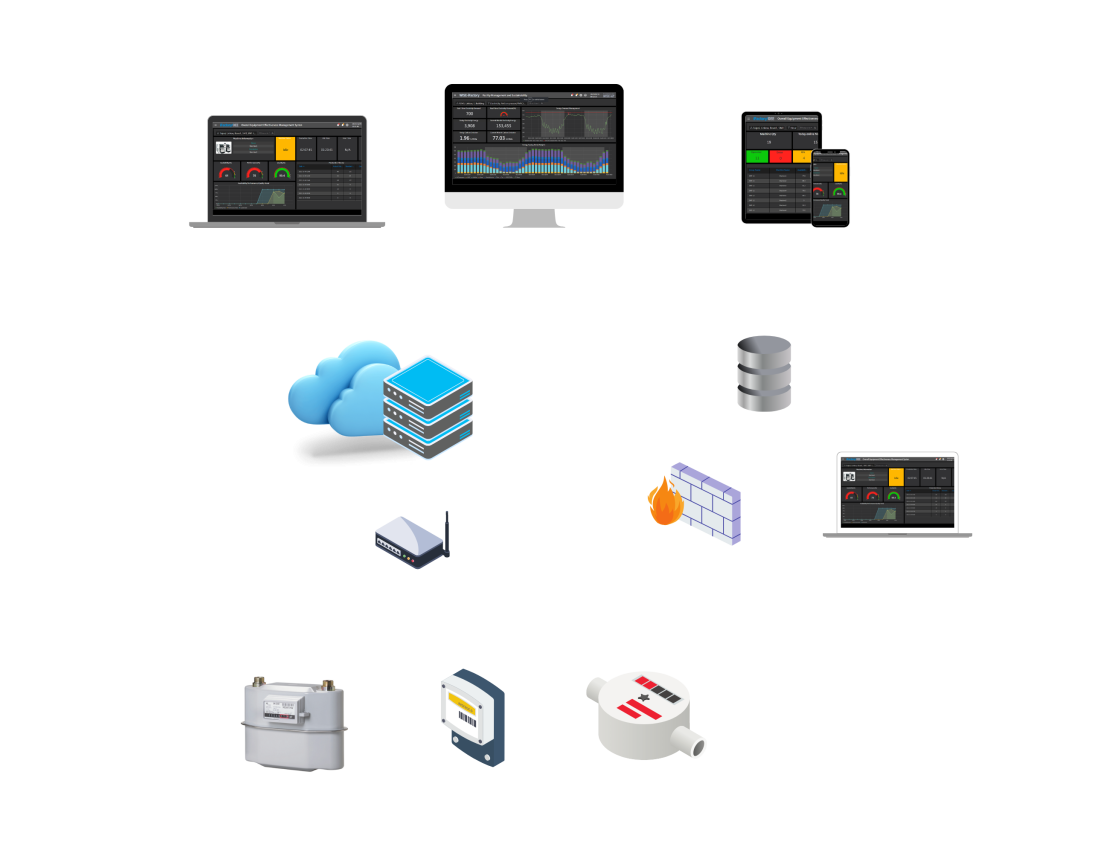

3 Steps to Enhance Your Factory Energy Saving with EMS

Data Acquisition

With WISE-PaaS/EdgeLink edge data acquisition software, data collected from different machines and multiple facilities goes through EMS edge into one single platform, either on-premises or in the cloud platform .

Data Computing & Visualization

With WebAccess/SCADA software, data can be aggregated in the FEMS server, or directly transmitted into the WISE-PaaS cloud platform. Data is analyzed and visualized as energy management assets with the iFactory/FEMS application.

Central Management

Using contextualized and visualized EMS data, both real-time and historical, in the Industry 4.0 Situation Room, supports managers to have continuous energy saving activities by PDCA cycle and visualization management.

Client Success Stories

See how we've helped businesses streamline their operations and increase efficiencies.